Zhuzhou Weilai New Materials Techonology Co., Ltd

Tel:0731-22160654

Mobile:

+8615773363955(Mr. Duan)

+8615200507438(Ms.Zhang)

E-mail:sales@rheniumcn.com

Fax:0731-22160654

Address:No.103, Building 2, Tiantai

Jingu Industry Park, Tian Yuan

District,Zhuzhou,Hunan,China

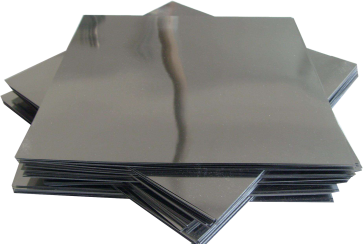

Tungsten rhenium alloy and molybdenum rhenium alloy

Rhenium is a chemical element,its Chemical symbol is Re,its Atomic number is 75, and it is a silvery white transition metal. Rhenium is rare, dense, and has multiple oxidation valences, with properties similar to manganese. Rhenium can be obtained from by-products of molybdenum extraction, and its alloys have superconducting properties.

Rhenium is expensive and alloys containing rhenium are often used in applications, with tungsten rhenium alloys and molybdenum rhenium alloys being the most widely used. Tungsten rhenium alloys contain 10% to 26% rhenium, while molybdenum rhenium alloys contain 11% to 50% rhenium. In addition, there are W-33.3Mo-33.3Re, Mo-Re-Hf-Zr, and Mo-Re-Hf-V alloys, with the latter two alloys having higher strength. Tungsten rhenium and molybdenum rhenium alloys have good high-temperature strength and plasticity, and can be processed into plates, sheets, wires, wires, and rods. They are used in high-temperature structural components, elastic components, electronic components, and other aerospace applications. They can also be used in the manufacturing of heating elements, workpieces, light bulbs, X-ray equipment, and medical devices. W-Re ThO2 alloy can be used as high-temperature heating workpiece, and tungsten rhenium and molybdenum rhenium alloy contacts have high resistance to thermal corrosion and high-temperature conductivity, which can improve the service life and working reliability of power supply equipment. For example, platinum rhenium alloy; Platinum tungsten rhenium alloy; Tungsten rhenium alloy; Molybdenum rhenium alloys, etc.

The ability to simultaneously improve the strength and plasticity of tungsten, molybdenum, and chromium is known as the "rhenium effect". Adding a small amount (3% to 5%) of rhenium can increase the initial recrystallization temperature of tungsten by 300 ℃ to 500 ℃. The above-mentioned effect of rhenium (Re) is known as the rhenium effect. W-Re and Mo-Re alloys have good high-temperature strength and plasticity, and can be processed into plates, sheets, wires, wires, and rods. They are used for high-temperature structural components (nozzles, nozzles, heat shields, etc.), elastic components, and electronic components in aerospace and aviation. The impact of rhenium (Re) on the microstructure, mechanical properties, unstable phases, and single crystal defects of single crystal high-temperature alloys is pointed out, and future research directions are pointed out.

Address:

No.103, Building 2, Tiantai Jingu Industry Park,

Tian Yuan District,Zhuzhou, Hunan, China.