Zhuzhou Weilai New Materials Techonology Co., Ltd

Tel:0731-22160654

Mobile:

+8615773363955(Mr. Duan)

+8615200507438(Ms.Zhang)

E-mail:sales@rheniumcn.com

Fax:0731-22160654

Address:No.103, Building 2, Tiantai

Jingu Industry Park, Tian Yuan

District,Zhuzhou,Hunan,China

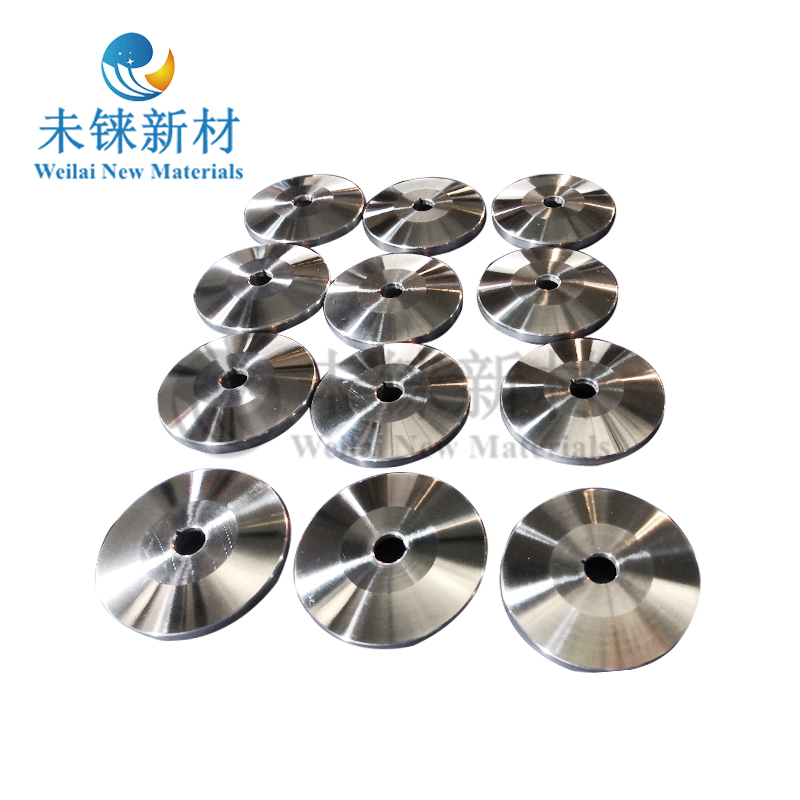

Rotating anode X-ray tubes have a rotating anode target that allows for higher power and better heat dissipation, resulting in smaller focal spots and sharper X-ray images. The anode target in rotating anode tubes is typically made of a composite material such as tungsten-rhenium alloy deposited onto a plate of molybdenum or TZM alloy.

The rotating anode target is designed to rotate at high speeds, typically around 3000-6000 revolutions per minute (RPM), to distribute the heat generated by the electron bombardment more evenly. This rotation reduces the heat concentration on a specific area and allows for higher power densities without compromising the focal spot size.

The tungsten-rhenium alloy is chosen for its high melting point, low vapor pressure, and ability to generate X-rays when bombarded with high-speed electrons. The molybdenum or TZM alloy substrate provides high thermal conductivity and fast heat dissipation to prevent overheating and cracking of the target.

Overall, the use of a rotating anode target with a tungsten-rhenium alloy deposited onto a molybdenum or TZM alloy substrate allows for higher power X-ray generation, smaller focal spots, and sharper X-ray images. This makes rotating anode X-ray tubes suitable for applications that require high-resolution imaging, such as medical diagnosis and industrial inspection.

Production Process:

Powder Preparation → Pressing → Sintering → Forging → Heat Treatment → Machining → Balancing →(Black Coating)→ Degassing → Packaging

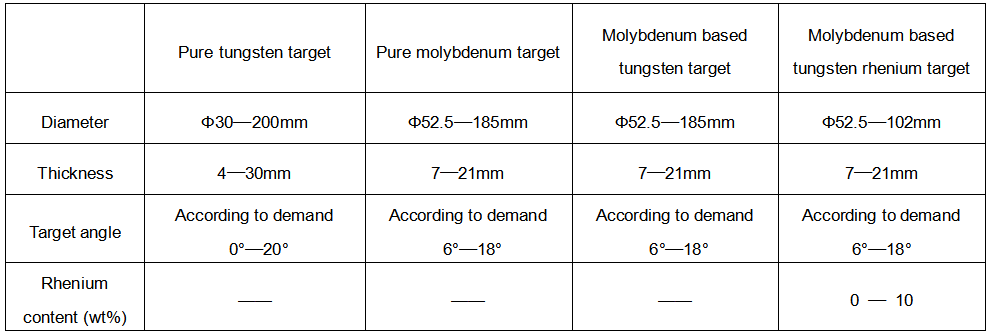

Production parameters of rotating anode X-ray tube:

(Other sizes can be customized as needed)

Address:

No.103, Building 2, Tiantai Jingu Industry Park,

Tian Yuan District,Zhuzhou, Hunan, China.