Zhuzhou Weilai New Materials Techonology Co., Ltd

Tel:0731-22160654

Mobile:

+8615773363955(Mr. Duan)

+8615200507438(Ms.Zhang)

E-mail:sales@rheniumcn.com

Fax:0731-22160654

Address:No.103, Building 2, Tiantai

Jingu Industry Park, Tian Yuan

District,Zhuzhou,Hunan,China

When the welding machine is working, the power and pressure of the spot welding machine itself determine the ability

to weld the enamelled wire packs, but whether it can be welded well, also has a lot to do with the electrode. Our company is here to introduce you as below:

The electrodes of the enamelled wire spot welding machine have three important functions. The first is conductive. The

welding current is introduced into the enamelled wire cable and terminal. The second is the conduction pressure, and

the third is to assist heating.

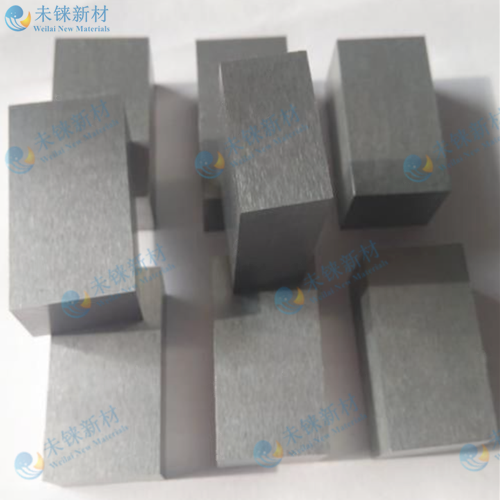

To maximize the above three conditions, the selection of electrode materials is very important. Generally, high-density

tungsten alloy materials or molybdenum alloy materials are used. This material can be conductive, resistant to voltage

resistance, and very easy to heat, which is convenient to destroy the insulating layer of the lacquer cable. At the same

time, the service life is long and resistant to oxidation.

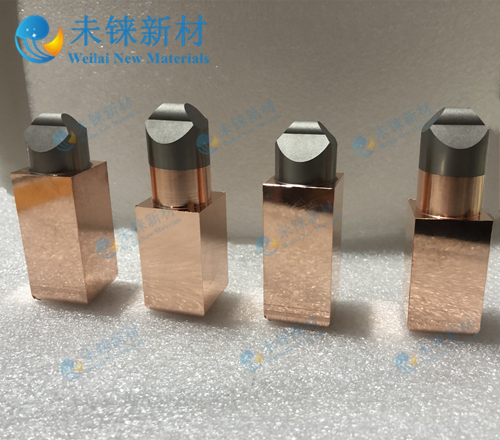

The shape and processing accuracy of the electrode is also very important. Generally, there are upper electrodes and

lower electrodes. The lower electrode is welded out of the copper pipe or copper terminal closer to the original copper

tube shape, with a small width and easy to connect with the insulation sleeve. And a set of flat electrodes can be

applied to welding various specifications of copper terminals or copper pipes, saving costs, and switching welding

models are faster. The design of the electrode seems simple, but it takes time to combine the actual welding effect to

improve.

Maintenance of the electrode is also very important. Although the hardness of tungsten and molybdenum electrode

materials is high, long-term welding is prone to cracks and damage. Therefore, proper maintenance and replacement

electrodes are conducive to extending the service life of the electrode.

Good enamelled wire welding machines also need good electrodes to match them to maximize the performance of

welding equipment!

Address:

No.103, Building 2, Tiantai Jingu Industry Park,

Tian Yuan District,Zhuzhou, Hunan, China.