Zhuzhou Weilai New Materials Techonology Co., Ltd

Tel:0731-22160654

Mobile:

+8615773363955(Mr. Duan)

+8615200507438(Ms.Zhang)

E-mail:sales@rheniumcn.com

Fax:0731-22160654

Address:No.103, Building 2, Tiantai

Jingu Industry Park, Tian Yuan

District,Zhuzhou,Hunan,China

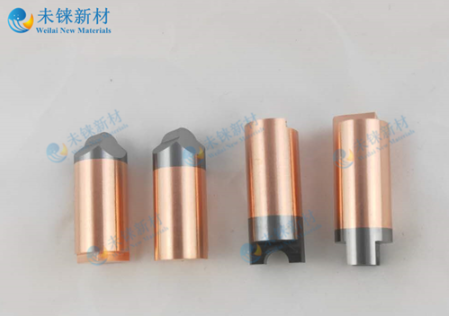

Electrodes are important components to ensure the quality of resistance welding, and should have functions such as conducting welding current, pressure, and heat dissipation to the workpiece.

The electrode material should have sufficiently high conductivity, thermal conductivity, and high-temperature hardness. The structure of the electrode must have sufficient strength, stiffness, and sufficient cooling conditions.

Due to the fact that the contact area of the electrode determines the current density, the resistivity and thermal conductivity of the electrode material are related to the generation and dissipation of heat. Therefore, the shape and material of the electrode have a significant impact on the formation of molten nuclei. As the deformation and wear of the electrode tip increase, the contact area increases, and the strength of the solder joint decreases, making maintenance of the electrode tip particularly important.

Material classification:

The first type: has the best conductivity and the worst strength. Such as copper and copper alloys, Cu Ag alloys, etc.

Suitable for welding parts that require high current density but poor high-temperature strength, such as welding aluminum and aluminum alloys, which can also be used for welding coated steel plates. It is also commonly used to manufacture conductive components that are not subjected to stress or low stress.

Type 2: Moderate conductivity and strength. Suitable for most components, the automotive industry adopts this type of copper alloy, such as Cr Cu (chromium bronze), Cr Zr Cu (chromium zirconium copper), etc.

This is the most commonly used electrode material, widely used for spot welding of low-carbon steel, low alloy steel, stainless steel, high-temperature alloys, copper alloys with low conductivity, and coated steel. Suitable for manufacturing various conductive components in resistance welding machines such as shafts, clamps, platens, electrode clamps, and arms.

Category 3: Poor conductivity, but best strength, especially at high temperatures, with higher mechanical properties and good wear resistance. Such as chrome zinc bronze, Mo, WCu, etc.

Suitable for welding stainless steel and high-temperature alloys with high strength and hardness.

Address:

No.103, Building 2, Tiantai Jingu Industry Park,

Tian Yuan District,Zhuzhou, Hunan, China.