Zhuzhou Weilai New Materials Techonology Co., Ltd

Tel:0731-22160654

Mobile:

+8615773363955(Mr. Duan)

+8615200507438(Ms.Zhang)

E-mail:sales@rheniumcn.com

Fax:0731-22160654

Address:No.103, Building 2, Tiantai

Jingu Industry Park, Tian Yuan

District,Zhuzhou,Hunan,China

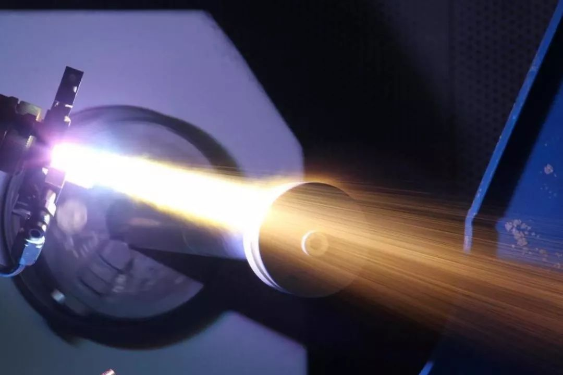

The previous article introduced the main factors that affect the quality of coatings, including plasma gas, arc power, and powder feeding. This article will continue to introduce the spray interval and spray angle, the relative motion speed between the spray gun and the workpiece, and the control factors of the substrate temperature.

④ Spraying interval and spraying angle: The interval between the spray gun and the workpiece affects the speed and temperature of the spraying particles and the substrate when they collide. The characteristics of the coating and spraying data are very sensitive to the spraying interval. If the spraying interval is too large, the temperature and velocity of the powder particles will decrease, and the bonding force, porosity, and spraying power will significantly decrease too small. This will cause the substrate temperature to rise too high and the substrate and coating will oxidize, affecting the bonding of the coating. When the temperature rise of the body is allowed, it is better to spray at a smaller distance.

Spray angle: refers to the viewpoint between the flame flow axis and the surface of the sprayed workpiece. When the angle is less than 45 degrees, due to the influence of the "shadow effect", the coating structure will deteriorate and form holes, leading to coating porosity.

⑤ The relative movement speed between the spray gun and the workpiece: The movement speed of the spray gun should ensure that the coating is flat and there are no traces on the back of the spray line. That is to say, the width of each stroke should be overlapped sufficiently to meet the above requirements. During spraying operations, a higher moving speed of the spray gun is generally selected to prevent partial overheating and surface oxidation.

⑥ Substrate temperature control: The more ambitious spraying process involves preheating the workpiece to the desired temperature during the spraying process, and then using jet cooling to maintain the original temperature during the spraying process.

Address:

No.103, Building 2, Tiantai Jingu Industry Park,

Tian Yuan District,Zhuzhou, Hunan, China.